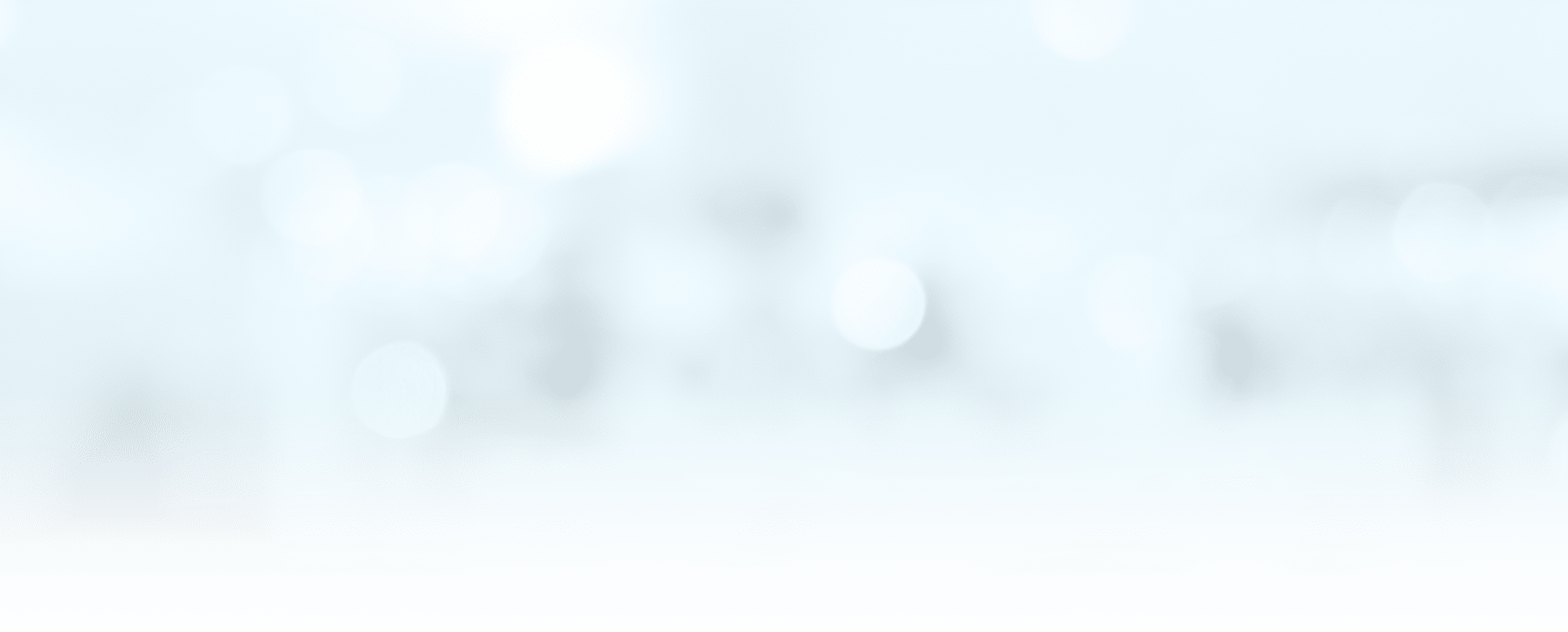

Meet us at these fairs and symposiums

Upcoming trade shows!

Devea at A3P in Lausanne from March 11 to 12, 2025

From March 11 to 12, 2025, Devea will cross the Swiss border to head to Lausanne for the A3P Congress. Come and exchange ideas with our team about recent innovations and research, and discover our new Phileas® products.

Pharmaceutical industry professionals, meet us in Lausanne to connect with Xavier, our partner Axon, and our Phileas®!

Devea at A3P Madrid on March 25 and 26, 2025

Devea at GMP Forum in Melbourne from March 31 to April 1, 2025

Devea in Cairo for the A3P Exhibition from May 14 to 15, 2025

Devea is pleased to announce its participation in the A3P Exhibition in Cairo from May 14 to 15, 2025! Come discover our latest innovations and solutions dedicated to the pharmaceutical and biopharmaceutical industries. This will be the perfect opportunity to engage with our experts, explore our products, and discover new opportunities for your projects.

We look forward to welcoming you on our booth to share this unique experience together!

Devea in Basel from May 22 to 23, 2025

Devea will be present at the PDA – Good Aseptic Manufacturing Conference in Basel, Switzerland from May 22 to 23, 2025.

We look forward to meeting you and sharing our innovative solutions to ensure optimal aseptic production conditions in the pharmaceutical industry.

Come discover our advanced technologies, designed to meet the strictest standards of quality and safety. We look forward to seeing you there to exchange best practices in aseptic pharmaceutical production! 💡🌍

Devea in Athens in June 2025!

Devea is excited to announce its participation in the FELASA Exhibition in Athens from June 2 to June 5, 2025!

Join us to discover our innovative solutions tailored to the needs of animal science research. This will be a great opportunity to meet our experts, explore our high-quality products, and discuss the latest advancements in the field.

We look forward to seeing you there to share this exceptional moment at the heart of scientific innovation!

Devea in Gothenburg for the PDA - Virus Conference from June 24 to 25, 2025

In 2025, the PDA Virus Conference celebrates its 15th anniversary! Devea will have the opportunity to participate from June 24 to 25, 2025, in Gothenburg, Sweden.

Come discover our Phileas® and meet our team: this must-attend conference in the pharmaceutical sector will be a fantastic opportunity to discuss ASD and your specific needs.

Devea in Constantine on September 25, 2025!

Devea is pleased to participate in the A3P exhibition in Constantine on September 25, 2025!

This event will be an opportunity to discover our latest innovations in air treatment and contamination control. The Devea team will be there to engage, share its expertise, and discuss solutions tailored to the needs of pharmaceutical industry professionals.

We invite you to come meet us and take advantage of this enriching experience!

Devea at CPHI in Frankfurt from October 28 to 30, 2025!

Devea will be present at the CPHI exhibition in Frankfurt! Come meet us to discover our innovative solutions dedicated to safety and quality in pharmaceutical production.

Meet Pierre Uminski and Charlotte Gourraud at booth 9.0D94 to explore our Phileas® devices.

We will be happy to share our latest advancements and discuss best practices in environmental control and risk management. Don’t miss this opportunity to strengthen your processes and improve your performance with Devea! 🌍💡

Innovation in surface disinfection in the pharmaceutical industry, not compromising with safety, performance and ease-of-use.

Airborne surface disinfection (ASD) has become an essential approach to ensuring safe and contamination-free production environments in the pharmaceutical industry.

At the A3P show in Tours, experts highlighted the importance of combining DSVA with barrier technologies such as RABS (Restricted Access Barrier Systems) and isolators. This synergy makes it possible to push back the limits of disinfection and maintain sterile, safe environments for the manufacture of vital medicines.

Reducing risks with ASD.

Automatic ASD works by diffusing disinfecting agents in mist form, covering all surfaces evenly. This method offers a number of advantages over traditional manual surface disinfection techniques. Firstly, it enables you to reach hard-to-reach areas and treat large surfaces in a short space of time.

What’s more, automatic DSVA eliminates the need to physically handle surfaces, reducing the risk of cross-contamination. Using appropriate disinfectants, DSVA can effectively eliminate bacteria, viruses, fungi and spores, creating a highly secure production environment.

Barrier technologies: a necessity to ensure safety for all.

However, to optimize the effectiveness of ASD, it is essential to combine this approach with the appropriate barrier technologies. RABS are restricted access barrier systems that prevent contamination of the production environment by limiting operator access and creating a physical separation between the operator and the production area. The integration of RABS with ASD ensures that disinfecting agents are confined within the production area, minimizing the risk of dispersal and external contamination. RABS also offer enhanced protection for operators, reducing their exposure to potentially dangerous pathogens.

Similarly, isolators play a crucial role in protecting sensitive operations and preventing cross-contamination. Isolators are hermetically sealed systems that enable hazardous substances to be handled in a controlled, confined environment. When combined with DSVA, isolators provide a double barrier of protection. The disinfecting agents released by the DSVA specifically target the surfaces inside the isolator, eliminating potentially present micro-organisms. This approach guarantees precise, targeted disinfection of critical areas, such as pharmaceutical product handling areas or package opening zones.

ASD: an important role in workplace safety.

Several concrete examples illustrate the effectiveness of integrating DSVA with barrier technologies. In the production of anti-cancer drugs, where the handling of potentially hazardous products is necessary, the combined use of DSVA, isolators and RABS helps to maintain optimal conditions of biocharge control while ensuring the safety of operators.

Similarly, in the manufacture of sensitive biological agents, DSVA combined with isolators eliminates the risk of contamination during delicate operations.

Barrier technologies and ASD: an effective combination.

In conclusion, the use of ASD in combination with barrier technologies such as RABS and isolators is revolutionizing surface disinfection in the pharmaceutical industry. This approach makes it possible to maintain highly sterile production environments, improve operator safety and prevent cross-contamination. A3P Tours has played a key role in highlighting these scientific advances and promoting their adoption in the industry.

Thanks to this synergistic combination, the pharmaceutical industry can continue to provide safe, high-quality medicines to meet society’s healthcare needs.

☛ Please do not hesitate to contact us to find out more about our services :