ASD in the pharmaceutical industry

You work in the most efficient environments. Additionally, your requirements are the guarantee of quality. Moreover, disinfection is a key step in your procedures. Therefore, this is why DEVEA mobilizes its expertise in ASD in the pharmaceutical industry.

How can DEVEA technology meet the needs of the pharmaceutical industry?

Despite the most rigorous processes, production rooms such as conditioner, filler, and airlock, can still be contaminated.

However, terminal disinfection can help you improve the safety of your products and boost productivity. In fact, DEVEA’s goal is to provide the pharmaceutical industry with the highest standard of disinfection (log₁₀ 6).

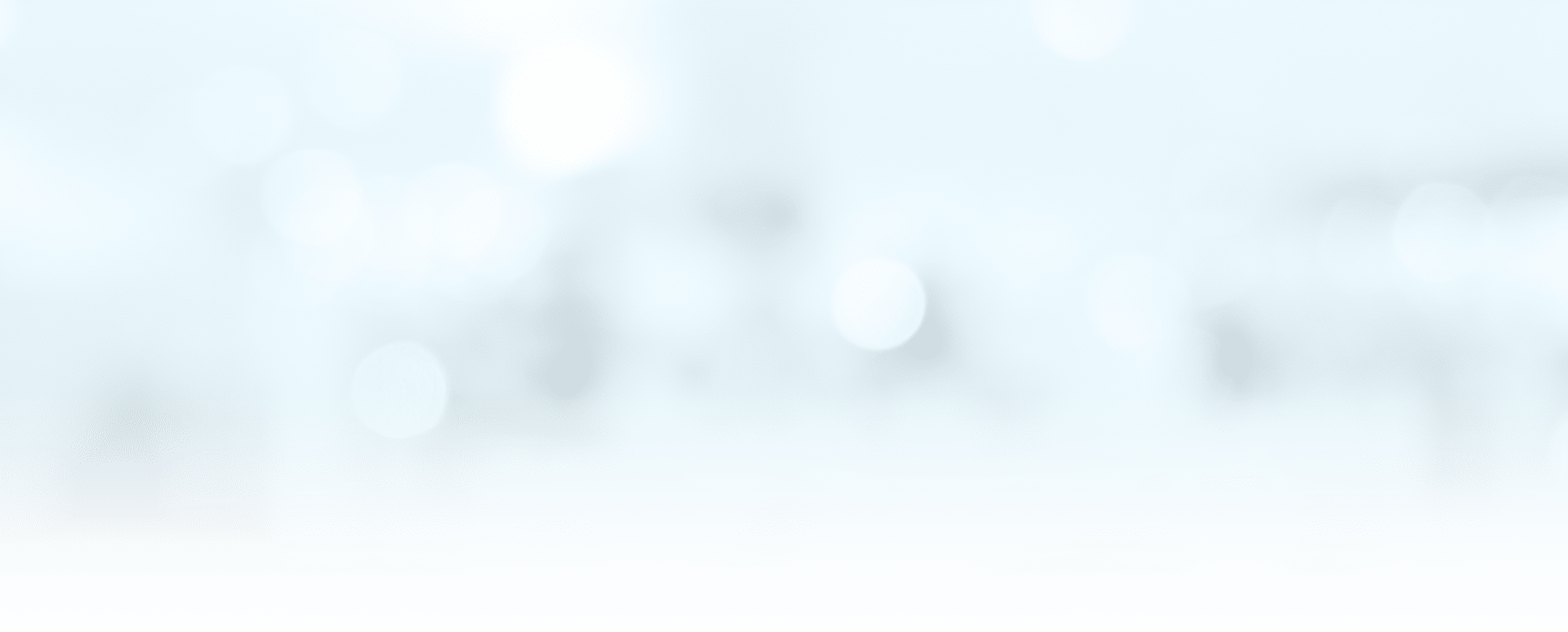

Therefore, we offer a wide range of machines and extensive expertise to achieve the best possible results. Specifically, our know-how in ASD for the pharmaceutical industry can help you achieve a zero contamination level.

ASD in pharmaceutical industry: a look into Devea's solutions

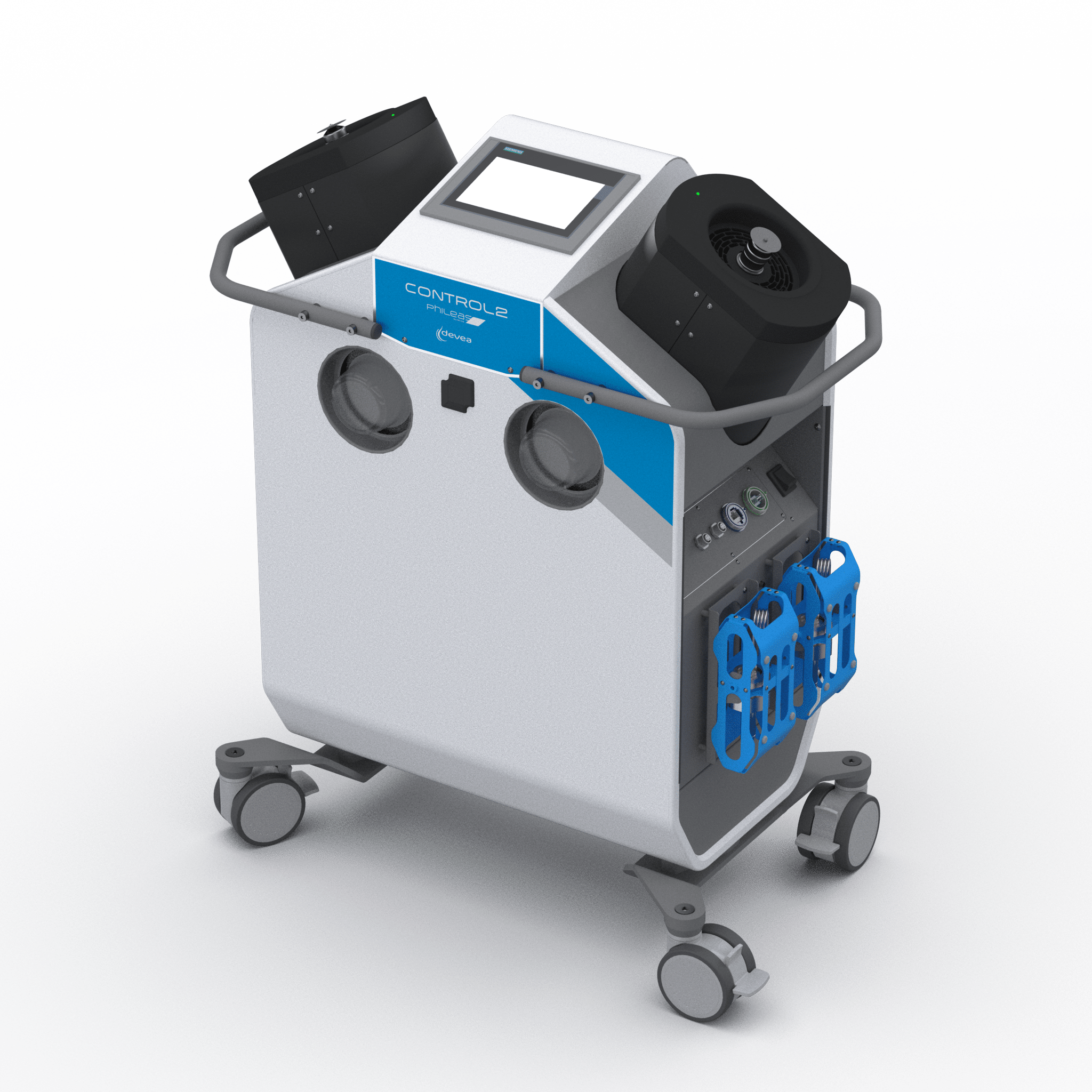

Phileas® utilizes the unique and innovative Microdrop technology. Moreover, the MicroDrop Technology developed by DEVEA ensures a perfectly homogeneous, replicable, and optimal treatment in the processed volumes.

Furthermore, the combination of Phileas® devices and either O2Safe or Phileasafe® disinfectants guarantees the effectiveness of the disinfection. Notably, this O2Safe-Phileas® pair has been granted the Marketing Authorization (AMM ANSES N. FR-2019-0071). Additionally, all tests required by the EN 17-272 standard have been performed by independent laboratories.

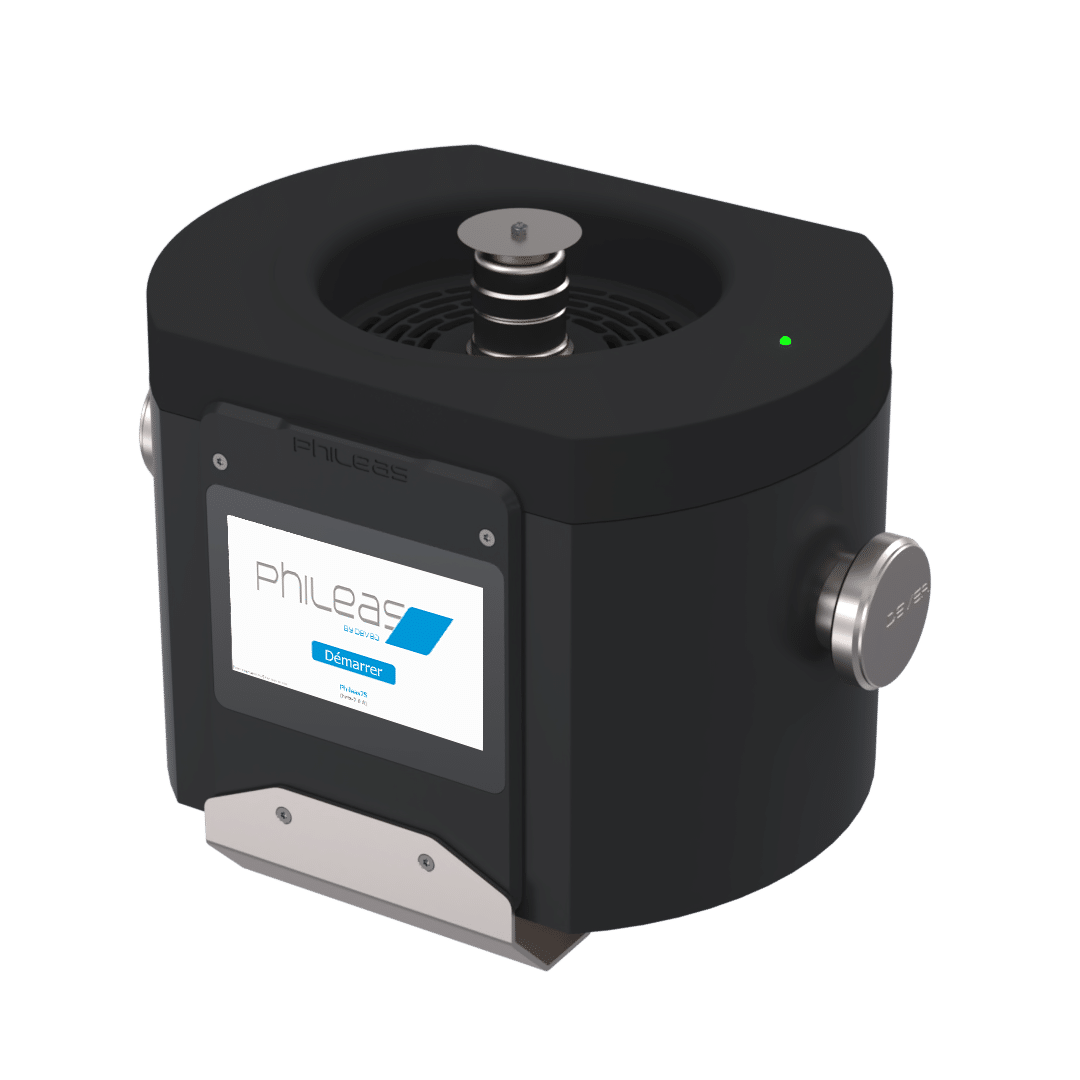

In addressing the challenges of the pharmaceutical industry, our wide range of machines, such as the Phileas® Genius (0.5 m3 – 5m3), the Phileas® 75 (up to 165m3), and the Phileas® 250 (800m3), allow us to provide comprehensive solutions.

Importantly, Devea’s ASD solutions for the pharmaceutical industry have been proven effective.

Proven results, tried and tested efficacy

The ASD methodology in the pharmaceutical industry is similar to that applied in other industries. However, the process may be different in the context of a BSC or laboratory space disinfection.

The ASD methodology in the pharmaceutical industry is similar to that applied in other industries. However, the process may be different in the context of a MSC or laboratory space disinfection.

Need identification

We are careful to establish a diagnosis of the situation to identify the specific needs of our clients.

Machine selection

Following the diagnosis, we select the most suitable ASD machine.

Testing with chemical or biological indicators

Tests are carried out upstream before launching the complete hygiene process.

Replicability of tests

Tests are reproduced for best results.

Deployement

The complete ASD process can now be started.

Our goal is to provide pharmaceutical industry professionals with an ultimate solution!

What are the outcomes of ASD in the pharmaceutical industry?

The effectiveness of the Phileas® / O2Safe process has been proven in many practical cases, reaching a greater than log₁₀ 6 level of disinfection. DEVEA has the expertise to guarantee results according to your requirements.

Additionally, our mobile systems, energy efficient, easy to set-up and to maintenance, provide you with a durable and high-performance solution.