Features of Phileas® CONTROL

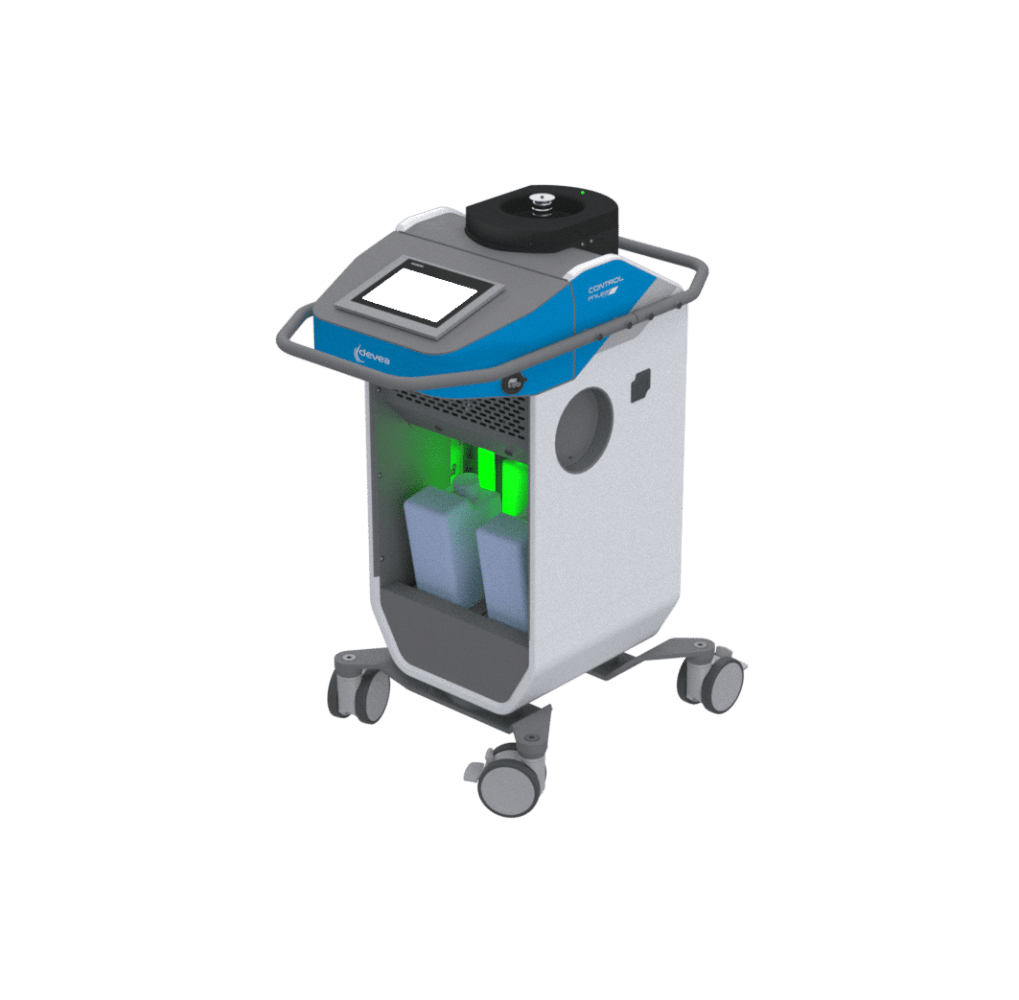

Developed with Airborne Surface Disinfection users, DEVEA’s Control range is the result of extensive consultation and two years of development. Integration, control, and safety are the key features of this range, which can handle all volumes. Here, Phileas® Control, for the most common rooms and volumes.

Learn more about the Phileas® CONTROL

How can a Class B room be decontaminated under GMP conditions with maximum safety and automation? Is it possible to launch the Airborne Surface Disinfection from the building management system and coordinate disinfection with the HVAC management and door opening? Can the equipment be integrated into the control and data acquisition system (SCADA) for a comprehensive view of the decontamination process? Is it possible to integrate hydrogen peroxide concentration data during treatment, including diffusion and contact time?

Discover Phileas® Control, designed with and for you, for standard volumes up to 300m3!

-

Volume treated: up to 165m3

Flow rate: 1200 mL/h

Droplet size: 5 to 10 µm

2 x 2L biocide containers, with weight sensor under each container

Modbus communication, RJ45 connection

Industrial automaton, Siemens display

Low maintenance, robust machine

Size (L x W x H): 976 x 830 x 485 mm

Weight: 19 kg

O2SAFE7,4 & Phileasafe® compatible materials

EN17-272 and AMM compliant

Terminal disinfection after space cleaning

-

- RFID reader for automatic reading of biocide data

- Optional H2O2 sensor

- Connection profiles with associated rights, when connecting to equipment

- Audit trail

- Complete traceability of operations

- Diffusion report with compliance

-

- Biodecontamination expertise with the most demanding sectors & Marketing Authorisation

- Devea Services:

- Protocol support & personalized advice

- Disinfection service provision

- Maintenance kit & step by step guided maintenance manual

- Biological and chemical indicators provision

- After-sale service & equipment repair diagnostic under 48hrs

- A range of products adapted for all volumes

- Design, manufacture and maintenance in France (Nantes)

Integration, safety, communication, control: treat your production areas routinely with a simple and reliable disinfection system. Fully compliant with regulatory requirements and industry performance expectations (6-log10 reduction in Geobacillus stearothermophilus spores), Phileas® Control equipment fits perfectly into contamination control strategies (CCS) for GMP sites producing sterile products in accordance with the new Annex 1 and seeking to optimize their industrial processes. Devea Biodecontamination Services’ expertise and support will help you quickly qualify and validate effective decontamination routines that integrate your constraints.

Watch the introductory video here

After-cleaning three-step disinfection

Diffusion

Microdrop Technology: the biocide sprayed in non-wetting fog covers the entire surfaces

Contact time

Small droplet size allows to shorten the evaporation time

Biocide enters the microbial cells and kills it

Aeration

Recovery after 20 air changes